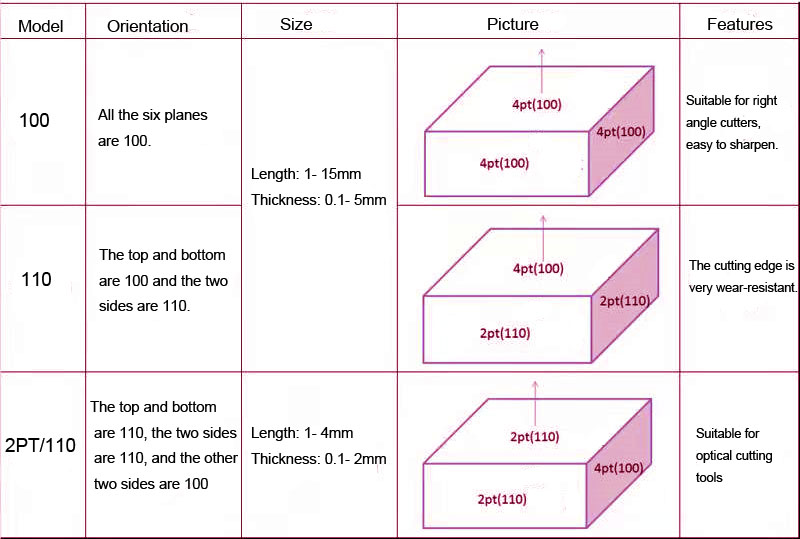

| Orientation: | |

|---|---|

| Thickness: | |

| Availability: | |

| Quantity: | |

CVD

INFI

| Crystal growth process: | Mono CVD |

| Color | Mechanical grade - Brownish |

| Advantage: | 1) Regular shape, uniform size. The size can be strictly controlled according to customer needs. |

| 2) High repurchase rate and high cost performance, well received by customers. | |

| 3) No visible growth lines, no black spots, no impurities, no crack. | |

| Orientation: | 100 (all 6 planes 100) |

| 110 (Top and bottom 100, four sides 110) | |

| 2pt/110 | |

| Shape: | Retangular |

| Edges | Laser Cut |

| Laser Kerf | < 3° |

| Lateral Tolerance: | +0.1/-0 mm |

| Roughness, Ra | Two sides polished, Ra < 30 nm |

| Thickness Tolerance | +/- 0.05 mm |

| Available size | 1mm - 15mm |

| Available thickness | 0.1- 5mm |

| Micro-hardness | 80-150Gpa |

| Young modulus | 1150-1130Gpa |

| Boron Concentration [B]: | <0.05 ppm |

| Nitrogen Concentration: | Mechanical grade 50 ppm - 100 ppm |

How to choose the orientation?

Generally speaking, if the diamond cutter is required to obtain the highest strength, the (100) crystal plane should be selected as the front and flank surfaces of the cutter,

if the diamond tool is required to resist mechanical wear, the (110) crystal plane should be selected as the front and rear of the cutter.

If the diamond tool is required to resist chemical wear, the (110) crystal plane should be used as the rake surface of the tool,

the (100) crystal plane as the flank surface, or the (100) crystal plane should be used for both the front and the flank surfaces.

| Crystal growth process: | Mono CVD |

| Color | Mechanical grade - Brownish |

| Advantage: | 1) Regular shape, uniform size. The size can be strictly controlled according to customer needs. |

| 2) High repurchase rate and high cost performance, well received by customers. | |

| 3) No visible growth lines, no black spots, no impurities, no crack. | |

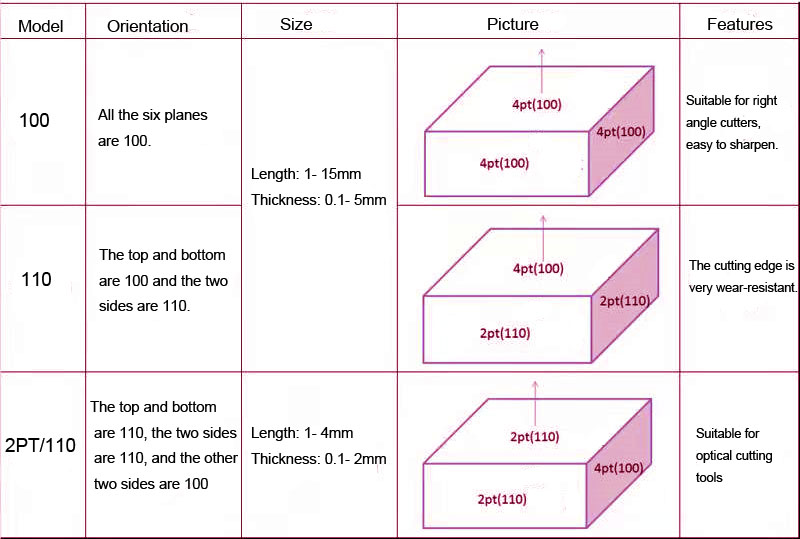

| Orientation: | 100 (all 6 planes 100) |

| 110 (Top and bottom 100, four sides 110) | |

| 2pt/110 | |

| Shape: | Retangular |

| Edges | Laser Cut |

| Laser Kerf | < 3° |

| Lateral Tolerance: | +0.1/-0 mm |

| Roughness, Ra | Two sides polished, Ra < 30 nm |

| Thickness Tolerance | +/- 0.05 mm |

| Available size | 1mm - 15mm |

| Available thickness | 0.1- 5mm |

| Micro-hardness | 80-150Gpa |

| Young modulus | 1150-1130Gpa |

| Boron Concentration [B]: | <0.05 ppm |

| Nitrogen Concentration: | Mechanical grade 50 ppm - 100 ppm |

How to choose the orientation?

Generally speaking, if the diamond cutter is required to obtain the highest strength, the (100) crystal plane should be selected as the front and flank surfaces of the cutter,

if the diamond tool is required to resist mechanical wear, the (110) crystal plane should be selected as the front and rear of the cutter.

If the diamond tool is required to resist chemical wear, the (110) crystal plane should be used as the rake surface of the tool,

the (100) crystal plane as the flank surface, or the (100) crystal plane should be used for both the front and the flank surfaces.