| Availability: | |

|---|---|

| Quantity: | |

INFI

Single Crystal Diamond Tools / MCD Diamond Tools

| Optional material | MCD,CVD,PCD |

| Diamond size | 0.25-0.8mm |

| Shank material | Stainless steel |

| Shank thickness | 6mm |

| Application apparatus | Faceting machine, CNC equipment |

1. This turning insert with diamond is widely used in ultra precise mirror turning, milling and cutting, etc.

2. It can be specially designed and produced for customers' need.

3. The raw materials give it strong hardness and high performance

4. You can inquire us for the specifications.

Material: Single-Crystal Diamond (Mono-crystalline)

Product Description

1 Physical characteristics

Diamond is a crystal of a single carbon atom, and its crystal structure belongs to the equiaxed face-centered cubic system (a system with the highest atom density). Since the bond between carbon atoms in diamond is sp3 hybrid covalent bond, it has strong binding force, stability and directionality. It is the hardest substance known in nature at present, its microhardness can reach 10000HV, and other physical properties are as follows.

Physical properties - numerical values

Hardness -60,000 to 100,000 MPa, depending on crystal direction and temperature

Bending strength -210~490MPa

Compressive strength -1500~2500MPa

Elastic modulus - (9 ~ 10.5) × 10 12 power MPa

Thermal conductivity -8.4~16.7J/cm·s·°C

Mass heat capacity -0.156J/(g·°C) (normal temperature)

Start oxidation temperature -900~1000K

Start graphitization temperature -1800K (in inert gas)

Friction coefficient between aluminum alloy and brass -0.05 to 0.07 (at normal temperature)

2,Product advantages

Due to the physical properties of single crystal diamond, it is not easy to stick to the knife and produce built-up edge when cutting. The surface quality is good. When processing non-ferrous metals, the surface roughness can reach Rz0.1~0.05μm. Diamond can also effectively process non-ferrous metal materials and non-metallic materials, such as non-ferrous metals such as copper and aluminum and their alloys, ceramics, unsintered hard alloys, various fiber and particle reinforced composite materials, plastics, rubber, graphite, glass. And a variety of wear-resistant wood (especially solid wood and plywood, MDF and other composite materials).

Single Crystal Diamond Cutting Tool

>>Diamond cutting tools are easily damaged, so the cutting edge should be covered with rubber or plastic caps when they are not in use.

>>Store them in separate containers when not in usage.

>>When inspecting and setting up,plz use optical instruments if possible.

>>Use copper shimstock or plastic between the cutting tools and micrometers or height gauges. If these are used, to avoid breaking the cutting edge.

>>Don't bring the diamond into contact with the work in a stationary position or stop the machine during the cut.

>>High speed reduces cutting edge pressure; low speed increases it, causing diamonds to break down more rapidly.

Vibration also shortens tool life, so machine tools should be in good condition.

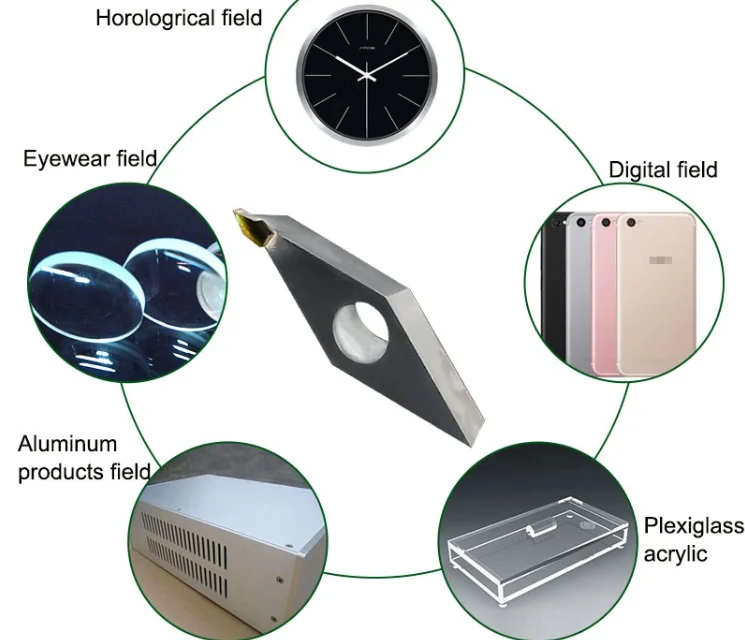

Application:

>>Making dressing tools for precise electric devices

>>Making cutting tools for non-metallic materials, non-ferrous materials, precious metal (gold, sliver, etc.), brittleness materials, aluminum alloys, advanced composites, nickel, copper, copper alloy, aluminum, acryl, etc.

__________________________________________________________________________________________________

Please let us know your needs and it would be better if you could bring a drawing.

We can provide you with the solution as soon as possible.

Single Crystal Diamond Tools / MCD Diamond Tools

| Optional material | MCD,CVD,PCD |

| Diamond size | 0.25-0.8mm |

| Shank material | Stainless steel |

| Shank thickness | 6mm |

| Application apparatus | Faceting machine, CNC equipment |

1. This turning insert with diamond is widely used in ultra precise mirror turning, milling and cutting, etc.

2. It can be specially designed and produced for customers' need.

3. The raw materials give it strong hardness and high performance

4. You can inquire us for the specifications.

Material: Single-Crystal Diamond (Mono-crystalline)

Product Description

1 Physical characteristics

Diamond is a crystal of a single carbon atom, and its crystal structure belongs to the equiaxed face-centered cubic system (a system with the highest atom density). Since the bond between carbon atoms in diamond is sp3 hybrid covalent bond, it has strong binding force, stability and directionality. It is the hardest substance known in nature at present, its microhardness can reach 10000HV, and other physical properties are as follows.

Physical properties - numerical values

Hardness -60,000 to 100,000 MPa, depending on crystal direction and temperature

Bending strength -210~490MPa

Compressive strength -1500~2500MPa

Elastic modulus - (9 ~ 10.5) × 10 12 power MPa

Thermal conductivity -8.4~16.7J/cm·s·°C

Mass heat capacity -0.156J/(g·°C) (normal temperature)

Start oxidation temperature -900~1000K

Start graphitization temperature -1800K (in inert gas)

Friction coefficient between aluminum alloy and brass -0.05 to 0.07 (at normal temperature)

2,Product advantages

Due to the physical properties of single crystal diamond, it is not easy to stick to the knife and produce built-up edge when cutting. The surface quality is good. When processing non-ferrous metals, the surface roughness can reach Rz0.1~0.05μm. Diamond can also effectively process non-ferrous metal materials and non-metallic materials, such as non-ferrous metals such as copper and aluminum and their alloys, ceramics, unsintered hard alloys, various fiber and particle reinforced composite materials, plastics, rubber, graphite, glass. And a variety of wear-resistant wood (especially solid wood and plywood, MDF and other composite materials).

Single Crystal Diamond Cutting Tool

>>Diamond cutting tools are easily damaged, so the cutting edge should be covered with rubber or plastic caps when they are not in use.

>>Store them in separate containers when not in usage.

>>When inspecting and setting up,plz use optical instruments if possible.

>>Use copper shimstock or plastic between the cutting tools and micrometers or height gauges. If these are used, to avoid breaking the cutting edge.

>>Don't bring the diamond into contact with the work in a stationary position or stop the machine during the cut.

>>High speed reduces cutting edge pressure; low speed increases it, causing diamonds to break down more rapidly.

Vibration also shortens tool life, so machine tools should be in good condition.

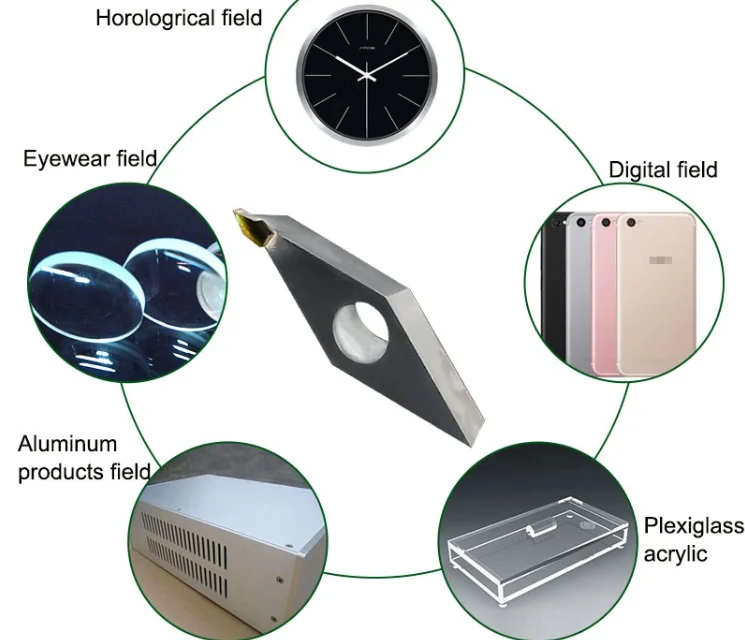

Application:

>>Making dressing tools for precise electric devices

>>Making cutting tools for non-metallic materials, non-ferrous materials, precious metal (gold, sliver, etc.), brittleness materials, aluminum alloys, advanced composites, nickel, copper, copper alloy, aluminum, acryl, etc.

__________________________________________________________________________________________________

Please let us know your needs and it would be better if you could bring a drawing.

We can provide you with the solution as soon as possible.