| Availability: | |

|---|---|

| Quantity: | |

scd23 SCD13 scd22 scd11

Infi

Harness the Ultimate Power of Electrochemical Oxidation with Our Boron Doped Diamond Electrodes

Confronting the challenge of destroying complex, persistent, and toxic organic pollutants in industrial wastewater requires a solution that is as powerful as it is durable. Our Boron Doped Diamond (BDD) Electrodes represent the pinnacle of anode technology, engineered to deliver unmatched performance and longevity in the most demanding electrochemical environments.

Core Technology & Superiority

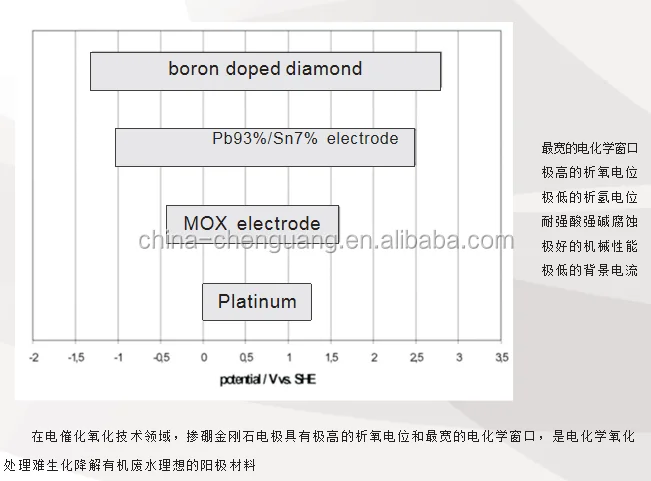

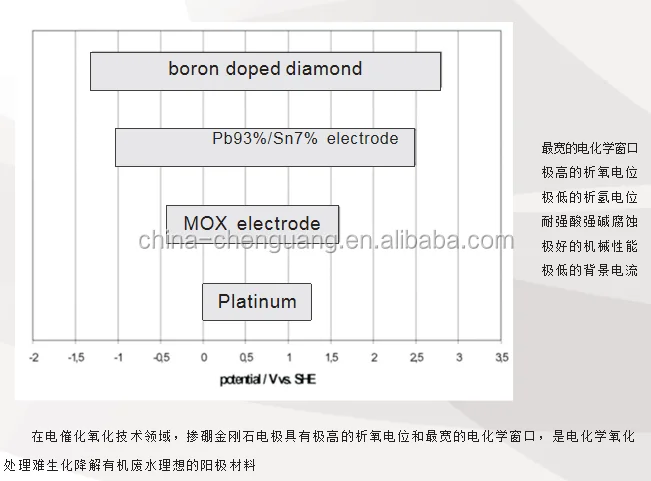

Our electrodes are fabricated by depositing a high-purity, polycrystalline diamond film doped with boron onto a robust substrate. This process creates a material that combines the legendary chemical inertness and physical hardness of diamond with excellent electrical conductivity. Unlike conventional metal or metal-oxide anodes that corrode, dissolve, or deactivate, our Boron Doped Diamond Electrodes offer an exceptionally wide electrochemical potential window. This key property allows them to generate extraordinarily high concentrations of hydroxyl radicals (•OH)—the most potent oxidants in aqueous electrochemistry—for complete contaminant mineralization, without significant electrode degradation.

Key Features & Benefits

Unrivaled Oxidation Power: Enables the complete mineralization of recalcitrant organic pollutants (e.g., pharmaceuticals, pesticides, dyes, complex organics) into CO₂ and water, achieving superior Chemical Oxygen Demand (COD) and Total Organic Carbon (TOC) removal.

Extreme Physical & Chemical Durability: Resists corrosion, fouling, and wear in highly acidic, alkaline, or saline wastewater streams, ensuring a dramatically longer operational lifetime compared to traditional anodes and reducing system downtime and replacement costs.

Broad-Spectrum Effectiveness: A versatile solution effective across a wide range of challenging applications, including the treatment of landfill leachate, coking wastewater, textile dye effluents, pharmaceutical wastewater, and for water disinfection.

High Energy Efficiency: The electrochemical stability and catalytic properties of the BDD surface can lead to more efficient pollutant degradation pathways, optimizing energy consumption per volume of treated water over time.

Primary Applications

Our Boron Doped Diamond Electrodes are the ideal choice for:

Advanced Electrochemical Oxidation (EO/EAOP) systems for industrial wastewater treatment.

Laboratory and pilot-scale research on pollutant degradation and electrochemical processes.

Specialized electrosynthesis and sensing applications requiring a stable, inert electrode material.

Engineered for Performance and Reliability

We provide robust electrode designs tailored for integration into various reactor configurations. By choosing our Boron Doped Diamond technology, you are not just purchasing an electrode; you are investing in a long-term, high-performance solution that pushes the boundaries of what is possible in electrochemical water treatment.

Contact us today to discuss how our BDD Electrodes can solve your most challenging water treatment problems and to request detailed technical specifications.

BDD electrodes can effectively degrade various organic waste water, such as organic waste water in the fields of medicine /agrochemicals, petrochemicals, coking, smelting, printing and dyeing,

papermaking, tanning, explosives, wine making, landfill leachate, etc.

| No. | Product Name | Substrates | Specs | Unit |

| 1 | BDD Electrode | Silicon, single side coated | 5*5*0.55mm | Piece |

| 2 | BDD Electrode | Silicon, double side coated | 5*5*1.0mm 2 holes open | Piece |

| 3 | BDD Electrode | Silicon, double side coated | 5*5*1.0mm 4 holes open | Piece |

| 4 | BDD Electrode | Silicon, double side coated | 8*6*1 Slotting | Piece |

| 5 | BDD Electrode | Silicon, double side coated | 7*7*0.5mm | Piece |

| 6 | BDD Electrode | Silicon, single side coated | 10*10*0.625mm | Piece |

| 7 | BDD Electrode | Silicon, double side coated | 10*10*0.625mm | Piece |

| 8 | BDD Electrode | Silicon, double side coated | 10*10*0.5mm | Piece |

Under the same conditions, the efficiency and energy consumption of BDD electrodes in degrading organics are significantly better than other electrodes

Although using P b O 2 plates or P t nets as anodes can effectively generate ozone, they have disadvantages such as low durability, high price, and harmful effects to the environment. Boron-doped diamond (B D D) electrodes have also been reported to produce ozone without the use of any electrolyte. The applications of B D D in extreme electrochemistry, such as wastewater treatment and the synthesis of hydroxyl and methoxy groups, have been well documented. Due to its excellent chemical and physical stability, B D D is used in ozone-generated anode materials.

CVD diamond BDD Application:

Firstly, BDD has an extremely high bandgap (about 5.47 eV), much higher than silicon (1.1 eV), silicon carbide (4H SiC, 3.2 eV), and gallium nitride (GaN, 3.44 eV). This characteristic makes it an ideal material for manufacturing high-temperature and high-frequency electronic devices. Secondly, BDD has the highest thermal conductivity among all known materials, which not only increases the operating temperature range of the device, but also significantly reduces the size and weight of the device, which is beneficial for manufacturing high-performance amplifiers and lasers.

In addition, BDD has the highest electron saturation rate under high electric fields, and its hole mobility is also the highest among all wide bandgap semiconductor materials. These characteristics make BDD particularly suitable for millimeter wave amplifiers and high-speed integrated circuits. At the same time, BDD also has excellent electron emission capability and can achieve negative electron affinity after special treatment, making it an ideal choice for making cold cathodes.

Not only that, BDD also performs well in key semiconductor performance indicators such as Johnson index, Keyes index, and Baliga index. For example, its Johnson index is as high as 8200, far exceeding 4H SiC (410) and GaN (280). This means that BDD has unparalleled advantages in power amplifiers, integrated circuits, and switching devices.

BDD has a wide range of applications, covering flat displays, microelectronics MEMS/NEMS、 Strong electricity and electrochemistry, among other aspects. Especially in electrochemical sensors, BDD has become an ideal material for the new generation of high-performance electrochemical sensors due to its high conductivity, wide potential window, low background current value, and excellent anti pollution ability.

Harness the Ultimate Power of Electrochemical Oxidation with Our Boron Doped Diamond Electrodes

Confronting the challenge of destroying complex, persistent, and toxic organic pollutants in industrial wastewater requires a solution that is as powerful as it is durable. Our Boron Doped Diamond (BDD) Electrodes represent the pinnacle of anode technology, engineered to deliver unmatched performance and longevity in the most demanding electrochemical environments.

Core Technology & Superiority

Our electrodes are fabricated by depositing a high-purity, polycrystalline diamond film doped with boron onto a robust substrate. This process creates a material that combines the legendary chemical inertness and physical hardness of diamond with excellent electrical conductivity. Unlike conventional metal or metal-oxide anodes that corrode, dissolve, or deactivate, our Boron Doped Diamond Electrodes offer an exceptionally wide electrochemical potential window. This key property allows them to generate extraordinarily high concentrations of hydroxyl radicals (•OH)—the most potent oxidants in aqueous electrochemistry—for complete contaminant mineralization, without significant electrode degradation.

Key Features & Benefits

Unrivaled Oxidation Power: Enables the complete mineralization of recalcitrant organic pollutants (e.g., pharmaceuticals, pesticides, dyes, complex organics) into CO₂ and water, achieving superior Chemical Oxygen Demand (COD) and Total Organic Carbon (TOC) removal.

Extreme Physical & Chemical Durability: Resists corrosion, fouling, and wear in highly acidic, alkaline, or saline wastewater streams, ensuring a dramatically longer operational lifetime compared to traditional anodes and reducing system downtime and replacement costs.

Broad-Spectrum Effectiveness: A versatile solution effective across a wide range of challenging applications, including the treatment of landfill leachate, coking wastewater, textile dye effluents, pharmaceutical wastewater, and for water disinfection.

High Energy Efficiency: The electrochemical stability and catalytic properties of the BDD surface can lead to more efficient pollutant degradation pathways, optimizing energy consumption per volume of treated water over time.

Primary Applications

Our Boron Doped Diamond Electrodes are the ideal choice for:

Advanced Electrochemical Oxidation (EO/EAOP) systems for industrial wastewater treatment.

Laboratory and pilot-scale research on pollutant degradation and electrochemical processes.

Specialized electrosynthesis and sensing applications requiring a stable, inert electrode material.

Engineered for Performance and Reliability

We provide robust electrode designs tailored for integration into various reactor configurations. By choosing our Boron Doped Diamond technology, you are not just purchasing an electrode; you are investing in a long-term, high-performance solution that pushes the boundaries of what is possible in electrochemical water treatment.

Contact us today to discuss how our BDD Electrodes can solve your most challenging water treatment problems and to request detailed technical specifications.

BDD electrodes can effectively degrade various organic waste water, such as organic waste water in the fields of medicine /agrochemicals, petrochemicals, coking, smelting, printing and dyeing,

papermaking, tanning, explosives, wine making, landfill leachate, etc.

| No. | Product Name | Substrates | Specs | Unit |

| 1 | BDD Electrode | Silicon, single side coated | 5*5*0.55mm | Piece |

| 2 | BDD Electrode | Silicon, double side coated | 5*5*1.0mm 2 holes open | Piece |

| 3 | BDD Electrode | Silicon, double side coated | 5*5*1.0mm 4 holes open | Piece |

| 4 | BDD Electrode | Silicon, double side coated | 8*6*1 Slotting | Piece |

| 5 | BDD Electrode | Silicon, double side coated | 7*7*0.5mm | Piece |

| 6 | BDD Electrode | Silicon, single side coated | 10*10*0.625mm | Piece |

| 7 | BDD Electrode | Silicon, double side coated | 10*10*0.625mm | Piece |

| 8 | BDD Electrode | Silicon, double side coated | 10*10*0.5mm | Piece |

Under the same conditions, the efficiency and energy consumption of BDD electrodes in degrading organics are significantly better than other electrodes

Although using P b O 2 plates or P t nets as anodes can effectively generate ozone, they have disadvantages such as low durability, high price, and harmful effects to the environment. Boron-doped diamond (B D D) electrodes have also been reported to produce ozone without the use of any electrolyte. The applications of B D D in extreme electrochemistry, such as wastewater treatment and the synthesis of hydroxyl and methoxy groups, have been well documented. Due to its excellent chemical and physical stability, B D D is used in ozone-generated anode materials.

CVD diamond BDD Application:

Firstly, BDD has an extremely high bandgap (about 5.47 eV), much higher than silicon (1.1 eV), silicon carbide (4H SiC, 3.2 eV), and gallium nitride (GaN, 3.44 eV). This characteristic makes it an ideal material for manufacturing high-temperature and high-frequency electronic devices. Secondly, BDD has the highest thermal conductivity among all known materials, which not only increases the operating temperature range of the device, but also significantly reduces the size and weight of the device, which is beneficial for manufacturing high-performance amplifiers and lasers.

In addition, BDD has the highest electron saturation rate under high electric fields, and its hole mobility is also the highest among all wide bandgap semiconductor materials. These characteristics make BDD particularly suitable for millimeter wave amplifiers and high-speed integrated circuits. At the same time, BDD also has excellent electron emission capability and can achieve negative electron affinity after special treatment, making it an ideal choice for making cold cathodes.

Not only that, BDD also performs well in key semiconductor performance indicators such as Johnson index, Keyes index, and Baliga index. For example, its Johnson index is as high as 8200, far exceeding 4H SiC (410) and GaN (280). This means that BDD has unparalleled advantages in power amplifiers, integrated circuits, and switching devices.

BDD has a wide range of applications, covering flat displays, microelectronics MEMS/NEMS、 Strong electricity and electrochemistry, among other aspects. Especially in electrochemical sensors, BDD has become an ideal material for the new generation of high-performance electrochemical sensors due to its high conductivity, wide potential window, low background current value, and excellent anti pollution ability.