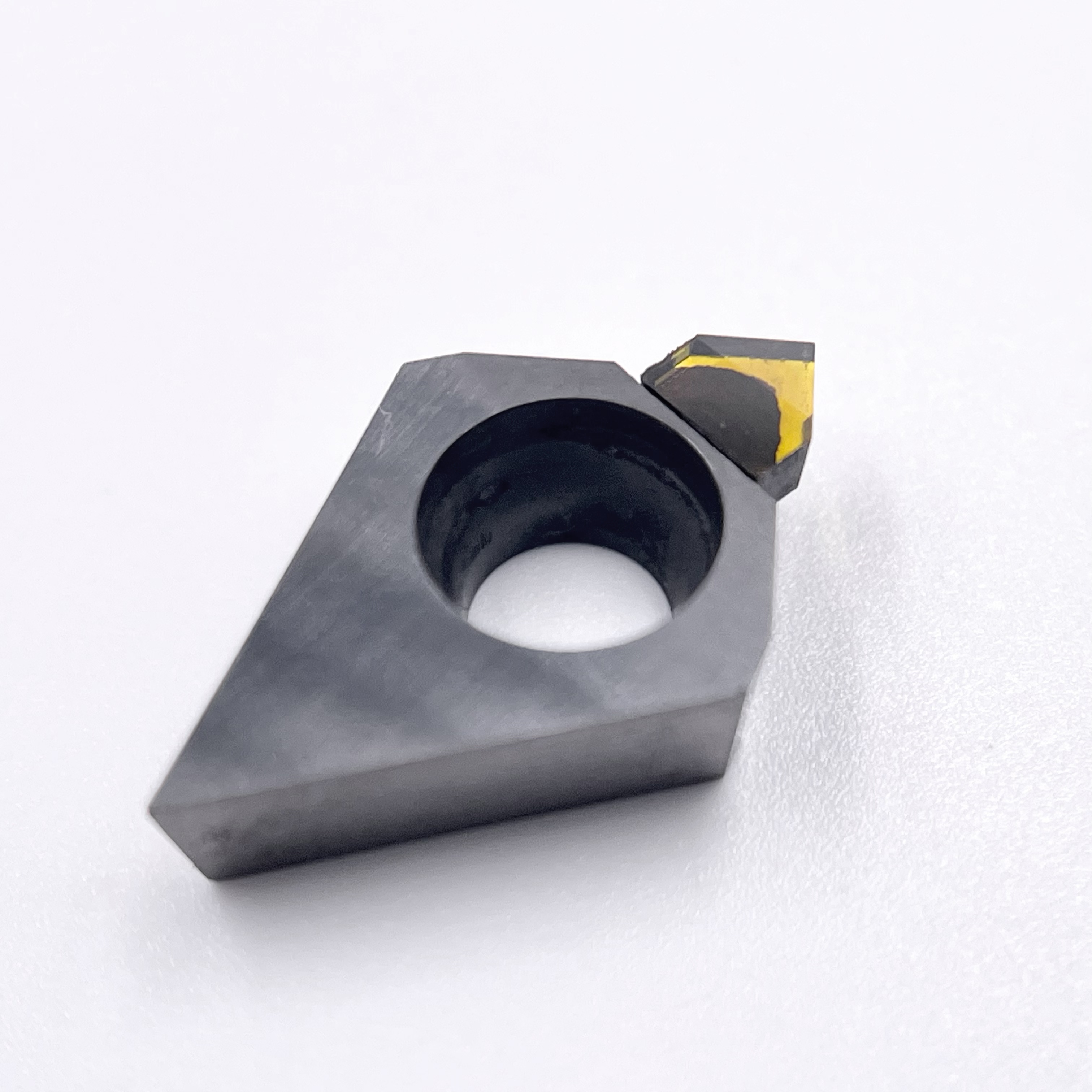

In the realm of ultra-precision manufacturing, where surface finishes are measured in nanometers and tolerances are vanishingly small, one material stands as the undisputed champion: the single crystal diamond. Tools crafted from this extraordinary material are not merely instruments; they are the key to unlocking levels of accuracy and surface quality unattainable by conventional means.

The supremacy of single crystal diamond tools stems from the perfect atomic structure of diamond itself. Composed of a single, continuous crystal lattice where carbon atoms are bonded via strong sp³ covalent bonds, it possesses a unique combination of properties. It is the hardest known natural material, with a microhardness reaching 10,000 HV. This inherent hardness translates to exceptional wear resistance, allowing the cutting edge to stay sharp for vastly longer periods. Furthermore, its extremely low friction coefficient (0.05-0.07 against non-ferrous metals) and high thermal conductivity are critical advantages.These properties work in concert to minimize heat buildup, prevent material adhesion to the tool, and eliminate built-up edges during cutting.

This synergy of properties directly enables single crystal diamond tools to achieve phenomenal results. They can produce optical-grade mirror finishes on non-ferrous metals, with achievable surface roughness as fine as Rz 0.1 to 0.05 μm. The cutting edge itself can be sharpened to a radius as small as 0.002 μm, allowing for incredibly precise and delicate machining operations. While natural diamond was the original source, advanced manufacturing techniques like Chemical Vapor Deposition (CVD) now enable the synthesis of high-quality single crystal diamond, expanding its availability and application potential.

The application spectrum for these tools is specialized yet vital for high-tech industries. They are exceptionally effective for machining a wide range of non-ferrous and non-metallic materials, including copper, aluminum, ceramics, various composites, plastics, and advanced polymers. This makes them indispensable in the production of components for optics, aerospace, and advanced electronics. For instance, their precision is crucial for manufacturing computer hard disk substrates, laser system optics, and other components where surface integrity is paramount.

Mastering single crystal diamond requires more than just the raw material; it demands precise orientation and craftsmanship. Diamond crystals are anisotropic, meaning their properties vary with crystallographic direction.Therefore, tools are meticulously oriented using techniques like X-ray diffraction to select the optimal crystal plane (such as the robust {100} plane) for the cutting faces, ensuring maximum strength and wear resistance.The subsequent grinding and polishing processes are equally precise, controlling parameters down to the nanometer level to create the flawless edge geometry required for ultra-precision work.

From enabling the next generation of optical devices to creating the intricate components that power advanced electronics, single crystal diamond tools represent the pinnacle of machining technology. They are the silent force behind the scenes, shaping the materials that shape our technological future.

In the precision-driven world of industrial wire manufacturing, diamond dies are the unsung heroes. These small but critical components, through which metal is pulled to reduce its diameter, directly determine production efficiency, wire quality, and operational cost.

When people hear "diamond," brilliance and jewelry often come to mind. However, in the world of advanced manufacturing and engineering, CVD Diamond represents a revolutionary engineered material, synthesized not for adornment but for unparalleled industrial performance. This article delves into the

In the precision-driven world of fine wire manufacturing, Diamond Wire Drawing Dies represent the ultimate tool for achieving consistent quality and extended tool life. Among these, dies crafted from Monocrystalline Diamond (MCD) with a precisely engineered {111} crystal orientation, synthesized via

In the demanding field of high-performance Diamond Optics, where systems are pushed to their limits by extreme power, heat, and harsh environments, materials must excel beyond conventional boundaries. Optical-grade diamonds produced by Chemical Vapor Deposition (CVD) achieve this, offering a unique

Faced with the critical task of eliminating persistent, toxic, and non-biodegradable organic pollutants from industrial wastewater, conventional biological or chemical methods often reach their limits. In this challenge, Boron Doped Diamond (BDD) technology emerges as a powerful and reliable advance

**Title: The Unmatched Precision of Single Crystal Diamond Tools**In the realm of ultra-precision manufacturing, where surface finishes are measured in nanometers and tolerances are vanishingly small, one material stands as the undisputed champion: the single crystal diamond. Tools crafted from this

At the heart of a precision laser, a transparent wafer less than two millimeters thick withstands the impact of thousands of watts of thermal energy, its surface temperature barely changing. This is not science fiction but an everyday miracle created by CVD Diamond Wafers in modern optical systems.A

Unlocking Precision & Durability: The Superiority of {111} CVD Diamond Wire Drawing DiesIn the demanding world of precision wire manufacturing, the quest for the perfect Diamond Wire Drawing Dies never ceases. Conventional dies, whether made of polycrystalline diamond (PCD) with binding agents or na

In the demanding world of high-power lasers, aerospace sensing, and advanced optics, the window material is not just a passive cover—it's a critical component that defines system performance, reliability, and limits. For applications where failure is not an option, Diamond Optical Windows engineered

Announcement No. 55 of 2025 by the Ministry of Commerce and the General Administration of Customs Decision on Implementing Export Controls on Items Related to Superhard Materials